Products >> Railcar Bogie Components >>

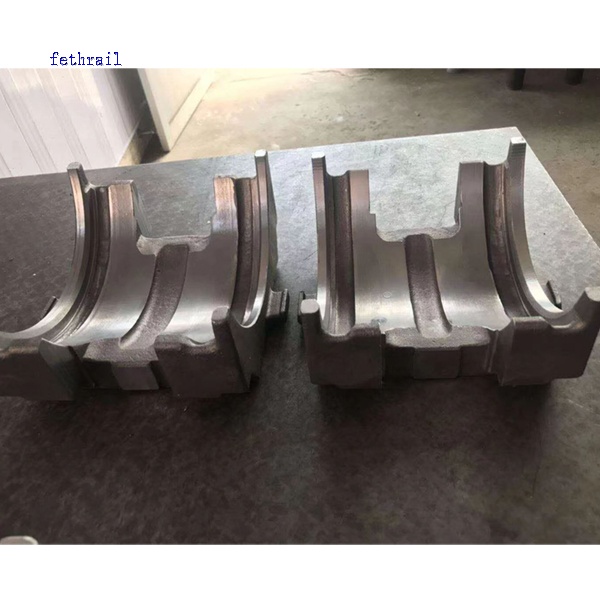

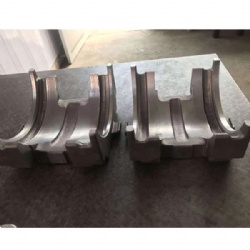

AAR Railway Bearing Axle Box of forged Parts

- Product No.:AAR Railway Bearing Axle Box of forged Parts

- Material:high-quality carbon steel

- Standard:AAR

- mould charge:yes

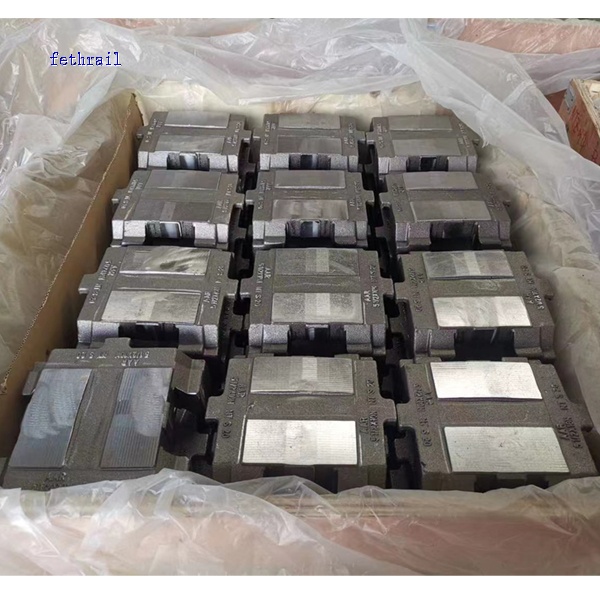

- Production time:60

- weight:18kgs

- Package:Wooden Box

The AAR Railway Bearing Axle Box is a crucial component used in railway vehicles to house the axles. Here's an optimized description:

An axle box serves as a sturdy housing that encloses the axle of a railway vehicle, providing support and facilitating the smooth rotation of the wheels. Typically constructed from durable materials such as cast iron or steel, the axle box plays a vital role in bearing the weight of the vehicle and transmitting it to the wheels. It is securely mounted on the chassis or bogie frame and incorporates axle bearings to ensure proper alignment and efficient operation.

Key Features:

-

1. AAR Standard Adapter: The AAR Railway Bearing Axle Box is designed to accommodate various AAR standard adapters, including sizes such as 5 X 9, 5 1/2 X 10, 6 X 11, 6 1/2 X 12, 6 1/2 X 9, 6 X 8, and 7 X 9. These adapters ensure compatibility and seamless integration with different railway systems and axle configurations.

-

2. Material: The axle box is manufactured using high-quality materials such as ZG230-450, B, B+, or C. These materials provide excellent strength and durability, enabling the axle box to withstand the rigorous demands of railway operations.

-

3. Specification: The AAR Railway Bearing Axle Box complies with the AAR M-924 specification, ensuring adherence to industry standards and specifications for optimal performance and reliability.

If you require a special adapter that is not listed, please inform us of your specific requirements, including the bearing type, side frame pedestal size, axle load, and any other relevant details. We are committed to meeting your customization needs and providing tailored solutions for your railway axle box requirements.

| Model | Dimension | Standard | Application | Net Weight(kg) |

| AAR C | 5〞×9〞 | AAR M-934 | Axle load ≤16t | 24.8 |

| AAR D | 5-1/2〞×10〞 | AAR M-934 | Axle load≤21t | 26.3 |

| AAR E | 6〞×11〞 | AAR M-934 | Axle load≤25t | 33.5 |

| AAR F | 6-1/2〞×12〞 | AAR M-934 | Axle load≤30t | 48 |

| AAR K | 6-1/2〞×9〞 | AAR M-934 | Axle load≤30t | 46 |

| AAR G | - | AAR M-934 | Axle load≤35.7t | 59 |

2 Parameters

|

Product name |

adapter |

|

Type |

5 1/2 X 10 |

|

Material |

AAR M-201 B+ |

|

Color |

Black |

|

Bore diameter (A) |

208 mm |

|

Bearign thrust shoulder spacing (B) |

155.6 mm |

|

Outer thrust shoulder lug spacing (C) |

74.6 mm |

|

Pedestal fit distance (D) |

156.4 mm |

The axle bearings play a critical role in the proper functioning of railway vehicles. Here is an optimized description of their features and maintenance:

The axle bearings are an integral part of the axle box assembly, providing support and facilitating smooth rotation while minimizing play and ensuring precise alignment. These bearings are preloaded to minimize any excessive movement and maintain optimal alignment. To reduce friction and wear between the bearing surfaces, lubrication is applied. Proper lubrication is vital for the longevity and performance of the bearings as it aids in heat dissipation and prevents metal-to-metal contact.

Maintenance and inspection of the axle boxes and bearings are essential to ensure the safe and reliable operation of railway vehicles. Regular maintenance routines include lubrication, cleaning, and thorough inspection for signs of wear, damage, or excessive play. Detecting any issues during inspections is crucial. If abnormalities or damage are identified, timely repair or replacement of the axle boxes or bearings is necessary to prevent further damage and ensure the safe operation of the train.

It is important to note that the design and configuration of axle boxes and bearings may vary depending on the specific type of railway vehicle, such as locomotives, freight cars, or passenger coaches. Different types of rolling stock may feature distinct axle box and bearing arrangements tailored to accommodate various operating conditions and specific requirements.

Products Category

Contact Us

Name: Meiya

Tel: +8617722574368

E-mail: info@fethrailmachinary.com

Skype: liumei-123@hotmail.com

WeChat: +8617722574368

Whatsapp: +8617722574368

Add: B1608 room Building 5 of Tainhe Huayuan ,YangJian Twon,Suzhou city ,Jiangsu ,China

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry