Products >> Railcar Bogie Components >>

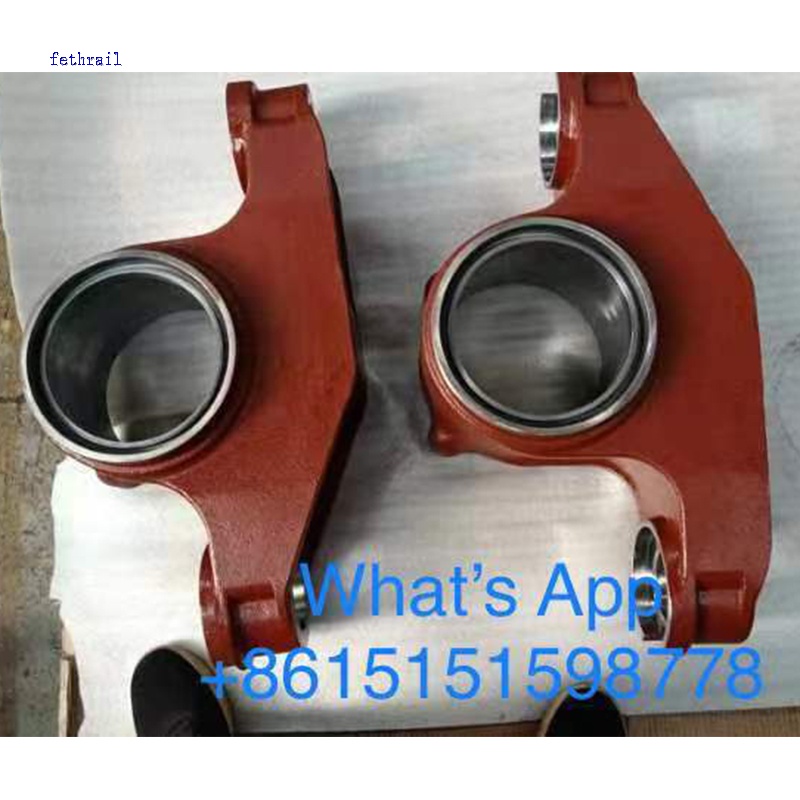

Bogie Axle Box of railway Bogie Casting manufacutre

- Product No.:2024125204348

- Material:high-quality carbon steel

- Standard:AAR

- mould charge:yes

- Production time:60

- weight:38

- Package:Wood Box

1) The Feed channel connects with the wheel set knocking down machine. After the Axle box going into the feed channel, the machine will finish the step of rotary washing and inwall derusting automatically. The sending axle box can be painted at once and then sent to the wheel set assembly line.

2) The un-washed, primary washed, secondary washed axle boxes are caught by the three manipulators, and sent to the primary washing, secondary washing and derusting machine to wash and derust. The three manipulators repeat the action step by step, and the axle box move forward on the production station.

3) The frames of the primary and secondary washings are the same. Each of the two washings cleans the axle box for three minutes. And it can be adjusted to the same speed with the wheel set knocking down machine. After the two three minutes washing, the cleanliness of the axle box will reach the technological requirements.

4) The derusting machine can catch the twice washed axle box sent by manipulator, and finish the actions of clamping, turning, centering, fastening, rotary derusting, turning back, letting down, and pushing out.

5) After adding detergent, the wash water can be recycled, and its temperature is 60-700C. The derusting wheelhead is sanding wheels.

Specification :

|

Type |

Bogie Casting Axle Box |

|

Standard |

TB T 2427-1993 |

|

Certificate |

ISO 9001,CRCC |

|

Production ability |

1000 Piece per month |

|

Material |

ZG230-450, Grade C/E cast steel |

|

Working temperature |

-40℃-+70℃ |

|

Size |

Customized |

|

Design lifetime |

5 years or 2.4*106, which comes first |

|

Guarantee |

12 months |

Products Category

Contact Us

Name: Meiya

Tel: +8617722574368

E-mail: info@fethrailmachinary.com

Skype: liumei-123@hotmail.com

WeChat: +8617722574368

Whatsapp: +8617722574368

Add: B1608 room Building 5 of Tainhe Huayuan ,YangJian Twon,Suzhou city ,Jiangsu ,China

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry